|

| Electric Heaters Machine |

| |

|

|

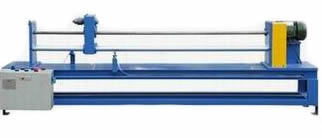

Rolling Machine |

Tube rolling machine Used to shrink the heating elements diameter and compact MgO powder.. Functions: 1. Machine frame: pig iron casting. 2. Two types of motor: non-unifo.

|

Used to shrink the heating elements diameter and compact MgO powder.

Functions:

- Machine frame: pig iron casting.

- Two types of motor: non-uniform speed and uniform speed.

- Two kinds of rollers: high speed steel and tungsten carbide roller.

- Characteristics: small size, low noise and convenient adjustments.

- Applicable tube: Copper, iron, aluminum, stainless steel, etc.

Main technical parameters:

- Tube diameter after shrinking: ¢5.2mm-¢19.0mm

- The Max. diameter before shrinking: ¢21mm

- The Min. length of tube:110mm

- Speed: 18meters/min.

|

| |

|

|

Filling Machine |

Three center-guarantee filling machine Fill MgO powder inside of empty tube. Mainly used for tube length over 2000mm. Functions: 1. PLC control, human-computer interface

|

|

|

Fill MgO powder inside of empty tube. Mainly used for tube length over 2000mm.

Functions:

1. PLC control, human-computer interface. Vibration frequency can be adjusted and vibration mechanism will go up along with the filling tube.

2. It adopts jet nozzle which assure almost zero MgO loss. Inner and outer filling tube makes better centering.

3. Powder filling density above 2.20g/cm3.

4. Big and small powder box design. Electronic adjusting the exposed length of terminal pin.

5. Indicate how to clear fault automatically.

6. 12, 18, 24, 36 and 48 position are available

7. Filling speed: 250-350mm/min

8. Tube diameter :below ¢16mm, tube length: below 5000mm.

Main technical parameters:

1. Power supply: Single phase 220V, 50Hz

2. Rated power: 2.0KW

3. Air supply: 5-7kg/cm2

4. Efficiency: 6500pcs/8h (tube length 250mm)

5. Packing size (L*W*H):8000*1950*1000(mm) (tube length 3meters)

10000*1950*1000(mm) (tube length 4meters)

12000*1950*1000(mm) (tube length 5meters)

|

|

|

|

Fill MgO powder inside of empty tube. Mainly used for tube length within 2000mm.

Functions:

1. PLC control, human-computer interface. Vibration frequency can be adjusted.

2. Powder filling density above 2.17g/cm3. Almost zero MgO loss.

3. Tube diameter: below ¢16mm.

4. Indicate how to clear fault automatically.

5. 12, 18, 24, 36 positions are available

6. Filling speed: 250-350mm/min

7. Min. tube diameter: ¢5.5mm

Main technical parameters:

1. Power supply: Single phase 220V, 50Hz

2. Rated power: 1.5KW

3. Air supply: 5-7kg/cm2

4. Efficiency: 6500pcs/8h (tube length 250mm)

5. It can fill 24pcs or 36pcs tubes at a time (below ¢10mm)

6. Packing size (L*W*H):3300*1050*1050(mm) (tube length 1meter)

4500*1050*1050 (mm) (tube length 1.5meters)

5800*1050*1050 (mm) (tube length 2meters)

|

|

|

|

Fill MgO powder inside of empty tube. Better used for big tube diameter.

Functions:

1. PLC control, human-computer interface. Vibration frequency can be adjusted.

2. Powder filling density above 2.17g/cm3. Almost zero MgO loss.

3. Tube diameter: below ¢18mm

4. Tube length: below 3000mm. It can be custom-made.

5. The guide tube moving speed controlled by frequency control.

6. 12, 18, 24 positions are available.

7. Filling speed: 250-350mm/min

Main technical parameters:

1. Power supply: Single phase 220V, 50Hz

2. Rated power: 1.5KW

3. Air supply: 5-7kg/cm2

4. Efficiency: 6500pcs/8h (tube length 250mm)

5. Packing size (L*W*):8000*1300*1000(mm) (tube length 3meters)

|

|

|

| |

|

| |

Coiling Machine |

|

Coiling machine Used to wind resistance wire into coil with very fast speed and can be used for different wire diameter, especially for tandem wire.

|

|

Used to wind resistance wire into coil with very fast speed and can be used for

different wire diameter, especially for tandem wire.

Functions

- NC system control, stable performance.

- Can program parameters as requirements

- Feeding droved by step motor, coil length can be adjusted

- Continuous working and automatic cut with clean ends

- The machine with small size, high accuracy, easy operation and high production.

Main parameters

- Power supply: Single phase 220±10% 50Hz

- Power: 1.45KW

- Feeding motor speed: 80m/min.

- Main shaft motor speed: 133/min.

- Coiling direction: right

- Min coil ID: over 3mm

- Wire diameter 0.1-0.55mm

- Machine size: 680*500*1400mm

- Weight: 360KGS

|

|

Used to wind resistance wire into coil(small diameter in two ends and big diameter in middle part), can be used for different wire diameter

Functions

- NC system control, stable performance.

- Can program parameters as requirements

- Feeding droved by step motor, coil length can be adjusted

- Continuous working and automatic cut with clean ends

- The machine with small size, high accuracy, easy operation and high production.

Main parameters

- Power supply: Single phase 220±10% 50Hz

- Power: 0.95KW

- Feeding motor speed: 80m/min.

- Main shaft motor speed: 133/min.

- Coiling direction: right

- Min coil ID: over 3mm

- Wire diameter 0.1-0.55mm

- Machine size: 320*500*1400mm

- Weight: 250KGS

|

|

Used to wind resistance wire into coils. It can wind both single and double wire.

Functions

- PLC control, operated by touch screen, count by coder, and measure resistance value automatically.

- The inverter controls the shaft speed. Coiling and cutting the coils automatically.

- Can set the parameters like wire diameter, Ohm/M, Ohm value in the touch screen.

- Cut by pneumatic cylinder, it can control the number of turns and with clean ends cut.

- The machine with small size, high accuracy, easy operation and high production.

Main parameters

- Power supply: Single phase 220±10% 50Hz

- Shaft rotation speed: 0-2134RPM

- Plastic wheel rotation speed: 0-74RPM

- Plastic wheel hole ID: ¢14mm, outer dia100-200mm

- Collet inner hole: ¢6.0 +0.05+0.01

- Motor rate: spindle motor370W/1340

- Plastic wheel motor: 60W/1400RPM

- Double roller motor: 120W/1400RPM

- Coil ID (mandrel diameter):0.75mm-12.7mm

- Wire diameter:0.10mm-1.0mm

- Packing size (L*W*H):780*870*1930(mm)

- Gross weight:188kg

|

|

Used to wind resistance wire into coils. It can wind both single and double wire.

Functions:

- The shaft speed controlled by DELTA brand inverter

- The machine will produce coils with very consistent resistance values

- When lack of wire or wire is broken, the machine will stop automatically. It also can count the output automatically.

- Wire with small diameter is usually cut by electromagnetic while wire with large diameter is cut by pneumatic.

- This machine with small size, easy operation and no operator required.

- Single and double plastic wheel are available.

Main technical parameters:

- Power supply: Single phase 220V 50Hz

- Rated power: 500W

- Shaft speed:0-2134rpm

- Plastic wheel speed: 0-74rpm

- Accuracy:±1%

- Coil ID (mandrel diameter):0.75mm-12.7mm

- Wire diameter:0.10mm-1.0mm

- Packing size (L*W*H):780*870*1930(mm)

- Gross weight:180kg

|

|

| |

|

|

Annealing Machine |

High frequency annealing machine Used to anneal round, square, straight heating elements and empty tube or rod completely.

|

|

Used to anneal round, square, straight heating elements and empty tube or rod completely.

Functions:

- High efficiency, little pollution, stable quality and safe.

- PLC control and easy operation

- Automatic feeding, the feeding speed can be adjusted, easy to change different specification.

Main technical parameters:

- Power supply: 3phase 380V, 50Hz (can be custom-made)

- Air supply:5-7 kg/cm2

- Rated power:30KW

- Packing size (L*W*H):6000*1200*1650(mm)

- Gross weight:850kg

|

|

Used anneal heating element and make it soft for bending.

Functions:

- Heating the heating elements surface by low voltage and high-current

- Can set the annealing time and temperature

- Pneumatic clamping, safe and convenient.

- Flexible design of copper collet

Main technical parameters:

- Power supply: 3phase 380V, 50Hz (can be custom-made)

- Air supply: 5-7 kg/cm2

- Rated power: 30KW

- Tube diameter: ¢6mm-¢20mm

- Tube length: 150 mm -2000 mm

- Packing size (L*W*H):2500*1000*1400(mm) (tube length 1.5meters)

- Gross weight: 500kg

|

|

| |

|

|

Bending Machine |

Fryer heater bending machine is one of our designed and manufactured bending machines. It can bend S.S and iron heater and adjust according to tube diameter

|

|

Rice cooker heater bending machine is used to bend heating element to the shape for rice cooker.

Functions:

- PLC control, easy operation and maintenance

- Hydraulic drive, stable performance

- High production

Technical parameters:

- Power supply:3phase 380V 50HZ

- Air supply:5-6kg/cm2

- Hydraulic pressure:60-65 kg/cm2

- Power:4KW

- Machine size:1650*700*1750mm

|

|

Fryer heater bending machine is one of our designed and manufactured bending machines. It can bend S.S and iron heater and adjust according to tube diameter.

Functions:

- PLC control, easy operation and maintenance

- Hydraulic drive, high production

Technical parameters

- Power supply: phase380V 50HZ

- Power: 4KW

- Weight: 700KG

|

|

Multi-O shape bending machine is a special designed machine for bending heating element ends, Multi-O shape and press heating elements.

Functions:

- PLC control, POD touch screen operation, easy operation and maintenance

- Servo motor control, the number of turns of O shape and pitch are very accurate

- The number of turns, pitch and speed can be adjusted

- Fault display automatically

Technical parameters

- Power supply:3phase 380V+/-10% 50Hz

- Air supply:5-7kg/cm2

- Power:3KW

- Tube diameter ≤10mm, central distance between two R≤2000mm, tube ends length≤100mm, O shape≤20mm, the layer length of O shape≤200mm

- Machine size:2660*880*2160mm

|

|

Spiral bending machine is used to bend heating element to spiral shape.

Technical parameters:

- Power supply: 3phase 380V 50Hz

- Power: 1.5KW

- Output capacity: 2800pcs/8h

- Machine size: 1350*680*1200mm

|

|

Finned heater bending machine.

Used to bend finned heater to U or M shape.

Functions:

- PLC control, POD204 touch screen operation, fault showing automatically and easy maintenance.

- Hydraulic drive, stable performance.

- High production.

Technical parameters

- Power supply: 3phase380V 50Hz

- Hydraulic pressure: 60-65KG/cm2

- Power: 4KW

- Tube diameter: 6.6-25mm (can be custom-made)

- Machine size: 2200*1350*1200mm

|

|

Finned heater bending machine. Used to bend finned heater to U or M shape.

Functions:

- PLC control, POD204 touch screen operation, fault showing automatically and easy maintenance.

- Hydraulic drive, stable performance.

- High production.

Technical parameters

- Power supply: 3phase380V 50Hz

- Hydraulic pressure: 60-65KG/cm2

- Power: 4KW

- Tube diameter: 6.6-25mm (can be custom-made)

- Machine size: 2200*1350*1200mm

|

|

| |

|

|

Cutting Machine |

Automatic tube cutting machine Used to cut copper, steel, aluminum and stainless steel tubes automatically.

|

|

Circle cutter, mainly used after tube making machine to cut the tube.

Functions:

- Test the speed and cut the tube automatically.

- PLC automatically controlled, touchscreen operation.

- Encoder read the data of length which assure the precision of cutting length.

- Even tube end and little burr.

Main technical parameters:

- Power supply:Triphase 380V 50Hz

- Air supply:5~7 kg/cm2

- Rated power:2.8KW

- Applicable tube diameter:5mm~12mm(custom-made)

- Applicable tube length:300mm ~6000mm

- Size(L*W*H):1800*700*1500(mm)

Weight: 850kg

|

|

Used to cut copper, iron, aluminum and stainless steel tubes manually.

Functions:

- Pneumatic clamping, automatic cutting.

- Element rotates, automatic stop when loading finished.

- Burr-free ends on the tubes, high efficiency, easy operation.

Main technical parameters:

- Power supply: 3phase 380V, 50Hz (can be custom-made)

- Rated power: 0.8KW

- Air supply: 5-7kg/cm2

- Tube diameter: ¢6-¢16mm

- Efficiency: 8000pcs-10000pcs/8h6

- Packing size (L*W*H):750*800*1150(mm)

- Gross weight: 170kg

|

|

Used to cut copper, steel, aluminum and stainless steel tubes automatically.

Functions:

- PLC control, automatic feeding and cutting.

- Tube length after cutting:150mm-2300mm

- Clean cut without burs

Main technical parameters:

- Power supply: 3phase 380V, 50Hz (can be custom-made)

- Rated power: 1.6KW

- Air supply: 5-7kg/cm2

- Tube diameter: ¢6-¢19mm

- Efficiency: 20000pcs-50000pcs (8.0mm copper tube)

- Packing size (L*W*H):6300*1100*1400(mm)

- Weight: 650kg

|

|

| |

|

|

Straightening Machine |

Straightening machine Used to straighten heating elements or empty tubes

|

Used to straighten heating elements or empty tubes

Functions:

- The height and angle of rollers can be adjusted

- Adopts hyperboloid roller design which can improve the surface and roundness of tubes.

- Easy to operate.

Main technical parameters:

- Power supply: 3phase 380V 50Hz (can be custom-made)

- Rated power: 1.5KW

- Tube diameter: ¢5mm-¢16mm (can be custom-made)

- Tube length: over 250mm

- Packing size (L*W*H):1500*850*1500(mm) (for 3stations)

2000*1000*1500(mm) (for 6stations)

- Gross weight: 450/950kg

|

| |

|

|

Turning Machine |

Auto-rotary trimming machine Used to take out the plastic plug from heating element ends and cut to preset length, especially for electric iron heating elements

|

|

Used to take out the plastic plug from heating element ends and cut to preset length, especially for electric iron heating elements.

Functions:

- PLC control, human-computer interface operation.

- Intelligent design, fault alarm automatically.

- Precise locating.

Main technical parameters:

- Power supply: 3phase 380V, 50Hz (can be custom-made).

- Rated power: 1.2KW

- Air supply: 5-7kg/cm2

- Efficiency: 4500pcs/8h

- Packing size (L*W*H): 800*800*1500(mm)

- Gross weight: 600kg

|

|

Used to take out the plastic plug from heating element ends and cut to preset length manually.

Functions:

- Pneumatic clamping and feeding.

- Cutting tool moves forward which make more safety.

- Hydraulic speed governor control the trimming speed

- Stable quality and easy operation.

Main technical parameters:

- Power supply: 3phase 380V, 50Hz (can be custom-made).

- Rated power: 0.8KW

- Air supply: 5-7kg/cm2

- Applicable tube diameter: ¢6mm-¢12mm

- Applicable tube length: ≥100mm

- Efficiency: 5000pcs/8h (below tube length 500mm)

- Packing size (L*W*H): 700*800*1200(mm)

- Gross weight:180kg

|

|

Used to take out the plastic plug from heating element ends and cut to preset length at the same time.

Functions:

- PLC control, human-computer interface operation. One person can operate three or four machines simultaneously.

- Automatic feeding and centering to ensure the two ends cutting length will be same and get the required length.

- Show how to clear the error automatically.

Main technical parameters:

- Power supply: 3phase 380V, 50Hz (can be custom-made)

- Rated power: 1.6KW

- Air supply: 5-7kg/cm2

- Tube diameter: ¢5.2mm-¢15mm

- Tube length: 110-1500mm

- Efficiency: 5500pcs/8h (below tube length 500mm)

- Packing size (L*W*H): 2700*880*1650(mm)

- Gross weight: 450kg

|

|

| |

|

|

Marking Machine |

Automatic stamping machine Used to mark the letter or number on the straight heating elements surface automatically.

|

|

Used to mark the letter or number on the straight heating elements surface manually

Functions:

- Cylinder drive,easy to operate,no power supply required.

- Tube diameter can be adjusted

Main technical parameters:

- Air supply: 4-7kg/cm2

- Tube diameter: ¢5mm-¢20mm

- Tube length: ≥100mm

- Efficiency: 5000pcs-8000pcs/8h

- Packing size (L*W*H):600*750*1100(mm)

- Gross weight: 100kg

|

|

Used to mark the letter or number on the straight heating elements surface automatically.

Functions:

- Automatic feeding,no operator is required.

- Tube diameter, length, print location can be adjusted.

- Easy to operate、stable quality

Main technical parameters:

- Power supply: Single-phase 220V, 50Hz

- Rated power: 200KW

- Air supply: 5-7kg/cm2

- Tube diameter: ¢5mm-¢20mm

- Tube length: 150mm-700mm (can be custom-made)

- Efficiency: 15000pcs-20000pcs/8h

- Packing size(L*W*H):1150*700*1500(mm)

- Gross weight: 230kg

|

|

| |

|

|

Testing Machine |

Testing machine Used to test high voltage, resistance or insulation of heating elements after rolling machine

|

Used to test high voltage, resistance or insulation of heating elements after rolling machine

Functions:

- Test high voltage and resistance automatically. Separate bad product automatically

- PLC control, easy to operate and no operator is required.

Main technical parameters:

- Power supply: single phase 220V 50Hz 500W

- Air supply:5-7 kg/cm2

- Efficiency:5000-8000pcs/8h

- Tube diameter: ¢6mm-¢12 mm

- Tube length:150 mm-800mm(can be custom-made)

- Packing size(L*W*H):1700*600*1000(mm)

- Gross weight:280kg

|

| |

|

|

Strip Reeling Machine |

Single head strip reeling machine Used to wind stainless steel strip on the heating elements

|

|

Used to wind stainless steel strip on the heating elements.

Functions:

- Controlling the segment pitch by change gears. It is very precise and stable.

- High efficiency can up to 1.6~1.7m/min.(5mm segment pitch).

- Easy to operate and stable quality.

- Make finned heater 2pcs at a time

Main technical parameters:

- Power supply: 3phase 380V 50Hz (can be custom-made)

- Rated power750KW

- Tube diameter: ¢6mm-¢13mm (can be custom-made)

- Tube length: 200mm-1800mm

- Packing size(L*W*H): 2500*750*800(mm)

- Gross weight: 350kg

|

|

Used to wind stainless steel strip on the heating elements.

Functions:

- Controlling the segment pitch by change gears. It is very precise and stable.

- High efficiency can up to 1.6~1.7m/min.(5mm segment pitch).

- Easy to operate and stable quality.

- Make finned heater 1pcs at a time

Main technical parameters:

- Power supply: 3phase 380V 50Hz (can be custom-made)

- Rated power750KW

- Tube diameter: ¢6mm-¢13mm (can be custom-made)

- Tube length: 200mm-1800mm

- Packing size(L*W*H): 2000*550*800(mm)

- Gross weight: 180kg

|

|

| |

|

|

Subulate Shrinking Machine |

Subulate shrinking machine Used to shrink the tube end.

|

Used to shrink the tube end.

Functions:

- Rotary flapping mode, stable quality.

- Applicable tube diameter:5~12 mm(cutom-made)

- Efficiency:5000~8000pcs/8h

Main technical parameters:

- Power supply: Triphase 380V 50Hz

- Rated power:750W

- Size(L*W*H):600*500*970(mm)

- Weight:180kg

|

| |

|

|

Cartridge Heater Machines |

Cartridge heater swaging machine Used to shrink the cartridge heater diameter

|

|

Functions:

- Argon arc welding, good quality.

- Autorotation welding.

- It can adjust the center of a circle according to the tube diameter.

- Tube diameter: below 25.4mm (can be custom-made)

Manin parameters:

- Power supply: single phase 220V+/- 10% 50Hz

- Rated power: 5KVA

- Efficiency: 4800pcs/8h

- Size: 1350*900*1900(mm)

- Weight: 150KG.

|

|

Used to fill MgO powder in the tubes.

Functions:

- It adopts PLC control, Electronic Governing control the vibration frequency.

- Tube diameter below 25.4mm, tube length 50mm – 1000mm

- Powder falling time and speed can be adjusted.

- 10, 12, 14, 16, 18, 20 positions can be choosen from according to your requirement.

Main parameters:

- Power supply: single phase 220V+/- 10% 50Hz

- Rated power:400W

- Air supply: 5-7kgf/cm2

- Efficiency: 4800pcs/8h (tube length 400mm)

- Size: 960*680*1800(mm)

- Weight: 300KG

|

|

Used to wind resistence wire on the MgO rod.

Functions:

- Step motor drive, the pitch can be adjusted.

- Stable performance, easy operation

- Easy to change different specification.

Main Parameters:

- Power supply: single phase AC 220+/-10% 50hz

- Power: 300W

- Applicable MgO rod diameter: ≤21mm

- Applicalbe MgO rod length: 60 to 800mm

- Dimension: 1560*600*1220mm

|

|

Used to shrink the cartridge heater diameter.

Functions:

- The machine can make the tube with good smooth finish.

- Operation mode: easy operation and maintenance.

- Small size, compact in structure, easy operation and good design.

Main parameters:

- Power supply: tri-phase 380V, 50Hz

- Power: 5.5KW

- Main shaft rotation speed: 272/rpm

- Motor rotation speed: 1450/rpm

- Feeding speed: 5-6m/min.

|

|

|

|

|