|

|

- Independent adjustment of Max and BIAS

- Down-opened Panel, easy for fuse replacement.

- VR of Max and SFS are installed in the front panel, easy for adjustment.

- Multi-LED display panel makes the operating condition clear.

- The auxiliary powers (ACI, AC2) are independently controlled for all models.

- Build-in buffering output adjustment (SFS VR), adjusting range 1~22 seconds. (Only for the phase control products)

- Top & bottom shielding covers are designed for safety and fashion out looking, also easy for wiring installation

- In case of 0.5 Hz sudden power losses, system output can switched off immediately.

- Once the power is restored, the system will buffer the output to prevent the voltage surge for fuse burn-down.

- Main power is one spec. Design for 200~480VAC.

- Automatic power frequency detection for 50~60 Hz. No need for selection or switch

- Automatic detection and display for power out-of-phase, SCR overheating, and fuse burn-down with one set of alarm dry contact output.

- In cases of SCR overheating or fuse burn –down, the system output is stopped immediately. Once the malfunction is eliminated and power is restored, the system will buffer the output to prevent the fuse burn-down.

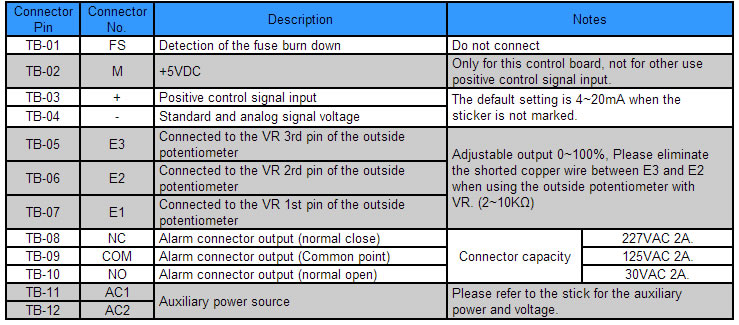

- 4~20mA, 1~5VDC, 2~10VDC, 0~20mA, 0~5 VDC, 0~10 VDC, Dry contact points, etc. and all control signals are ready to use.

- Triggering circuit and the main board are designed separately to avoid the main board damage when main circuit malfunctions.

- Using European detachable control signal connector for easy replacement without re-wiring installation.

|

Outline descriptions:

|

| Installation and ambient conditions: |

- When the power regulator is operating, the heat will be generated automatically. Please install the system vertically and leave some empty space on two sides to aviod the temperature inside the regulator rising continuously.There must be some ventilation holes on the control box. Please follow the principle of hard air rising to intall the ventilation holes or estra cooling fans.Please avoid installing the regulator in the place with high temperature or poor ventilation. Otherwise, the maximum operating capacity must be set lower than 70% of the nominal capacity.Avoid installing the regulator in the places with heavy water evaporation, acid, alkaline, or corrosive air.Ambient humidity: below 90% RH (no condensation)

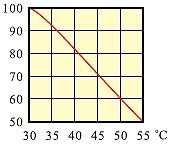

- Ambient temperature: -10-45℃

|

|

|

The above numbers are based on the conditions of no erosion, no greasy dirt, and no cover on the heat sink and following the recommended installation guides based on the principle of heat transfer. |

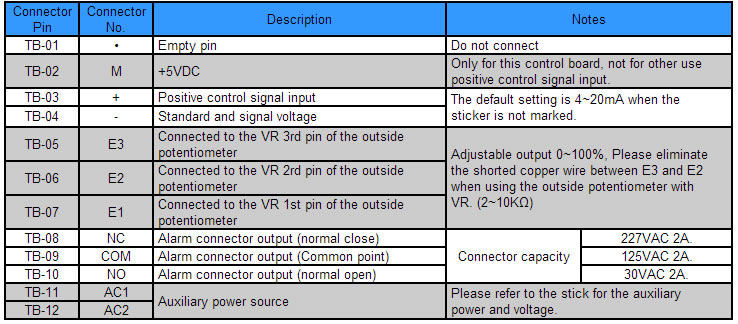

- Control and applied

loading

- Control panel

and applied load

- Selection of

the input signal

- Connection

specifications

|

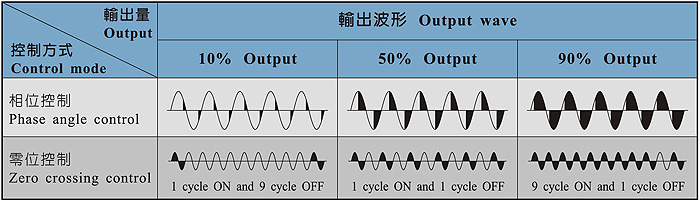

- Phase angle control:

Continuous phase angle control, steady output, current gauge reading remains steady. But, every half wave will produce harmonic wave.

- Applicable loading:

Fixed resistance loading, variable resistance loading, inductive loading, IR light bulb.

- Zero crossing control:

Distributed zero crossing control, minimum resolution 1 Hz, no harmonic wave, and current gauge reading oscillates.

- Applicable loading:

Fixed resistance loading.

|

| Wiring and setup notices: |

|

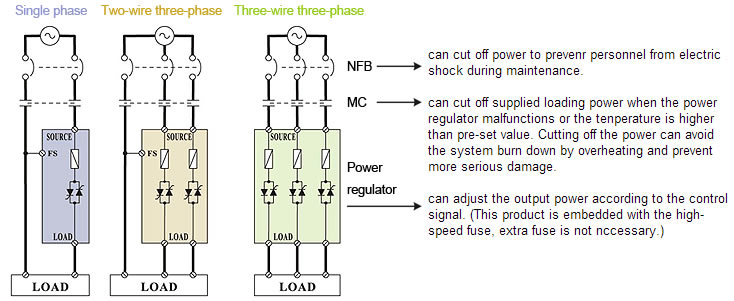

- Standard main circuit setup: main power→molded case circuit breaker→contactors→power regulator→loading.

- The screw must be tightened during the wiring setup to avoid high temperature resulting from bad contact.

- Once the wiring setup is completed the front panel and safety cover must be properly installed before the system is powered up to avoid the electric shock or shot circuit caused by dropped conductive objects.

|

Single phase, Single phase zero crossing, Two-wire three-phase zero crossing (SP, SZ, TZ) |

|

| |

| Three-wire three-phase angle, Three-wire three-phase zero crossing (TP, ZZ) |

|

| |

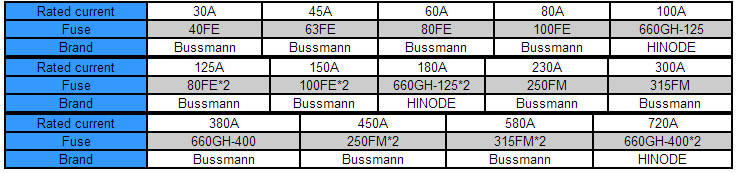

| Applicable high-speed fuse for the power regulator |

|

|

|

|

|